I spent the afternoon modding the ATX power supply to turn on without a motherboard, soldering up the stepper drivers and opto-endstops, uploading the Sprinter firmware to the Mega 2560, and wiring a shielded cable for the Y-axis. I had to tinker with the configuration file a bit to turn off the endstops for now- I don't have any plugged in so repsnapper refused to move motors without them. But once I got the settings right the Y-axis started responding to the simple move commands in repsnapper!

I've been using an old Hako 927 soldering iron for all of the electronics - and also for all of the crimped connectors for the wiring into the RAMPS. It was a reject from work, but has settable temperature control and can be set up with a ground for ESD electronics soldering. It's probably 20 years old but still works like a champ.

I add a bit of solder after I crimp on the connectors before I insert them into the connector housing. I have had trouble in the past with crimped connectors working loose and creating intermittent shorts- a real pain in the ass to troubleshoot. The list of things to work on is starting to get shorter, and I haven't run into any major snags so far...

To do: wire up Z-axis, wire up X-axis, finish hot end, install and wire extruder, install print bed, install and wire endstops.

Friday, June 17, 2011

Chassis finished, RAMPS soldering fun

I finished up the chassis build this morning by installing the X-axis motor and belt, and tuning everything up one more time. All axes seem to move with very little effort- the motors seem to add more resistance than the slides so I 'think' I'm ok.

I also worked on the Makergear hot end- soldering the teflon coated wires and adding the last of the ceramic adhesive. My final nichrome resistance is about 6.3 ohms, so that should be roughly 2 amps supplied at 12 volts.

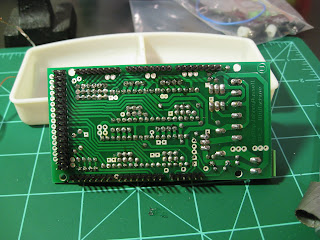

I also soldered up the RAMPS 1.2 board. Makergear shipped me the ultimachine V1.2 package. I would rather have had 1.3 but I'm just being picky. Before and after shots:

I still have to solder the stepper driver boards and opto-endstops, then I'll start experimenting with uploading the Sprinter firmware to the arduino and see if I can keep the magic smoke inside all the chips.

I also worked on the Makergear hot end- soldering the teflon coated wires and adding the last of the ceramic adhesive. My final nichrome resistance is about 6.3 ohms, so that should be roughly 2 amps supplied at 12 volts.

I also soldered up the RAMPS 1.2 board. Makergear shipped me the ultimachine V1.2 package. I would rather have had 1.3 but I'm just being picky. Before and after shots:

I still have to solder the stepper driver boards and opto-endstops, then I'll start experimenting with uploading the Sprinter firmware to the arduino and see if I can keep the magic smoke inside all the chips.

Wednesday, June 15, 2011

X-axis and cold extruder build

I continued with building the X-axis and the extruder drive mechanism. The X-axis blocks have about 10 captured M3 nuts- insanely difficult to install and align. I got them all in but it looks like I stressed some of the plastic on one of them a little too much while tightening the axis rod. I'll add pictures tomorrow. The extruder drive went together cleanly- I was glad of the note to install one of the captured M4 nuts before installing the geared stepper. Looks like I will work on the X-Z axis interface tomorrow and start building the hot end. Hopefully I'll be soldering up the RAMPS over the weekend and get some first motion next week.

Building the frame and Y-axis

So I finally got down to business today and started the mechanical assembly. Assembling the frame and Y-axis took about 2.5 hours, give or take. I used the Prusa build instructions [here] while cross referencing the Makergear specific changes [here]. So far things have gone pretty smoothly. Getting the Y-axis to slide smoothly took a little coaxing- a lot of wiggling f the linear rods and fine tuning of the bar clamps on the ends. I think it is smooth enough to run well, but overall it is a bit finicky.

Finding all the proper hardware to assemble the Y-axis took a while- there was a plastic bag of miscellaneous bolts, washers and nuts which had the right sizes to make things work. I ended up getting out the calipers to verify that I had the right M3x12 bolts for the wooden frame. Also- the 3rd bolt that holds the Y-axis motor to its bracket would not fit in the space next to the idler wheel. For now I'm going without it, I'll kludge a solution if I determine I really need the extra strength.

Finding all the proper hardware to assemble the Y-axis took a while- there was a plastic bag of miscellaneous bolts, washers and nuts which had the right sizes to make things work. I ended up getting out the calipers to verify that I had the right M3x12 bolts for the wooden frame. Also- the 3rd bolt that holds the Y-axis motor to its bracket would not fit in the space next to the idler wheel. For now I'm going without it, I'll kludge a solution if I determine I really need the extra strength.

Tuesday, June 14, 2011

Playing with Skeinforge

I spent some time today building a 3d model of a calibration plate for testing my printer, and decided to do some reading up on Skeinforge settings [Skeinforge FAQ]. The FAQ is actually pretty laid out with what the different settings do with example photos of many of the changes in settings. So here is a screenshot of one of the solid layers showing the beginning. I am designing some relatively shallow calibration parts to allow for quick printing and changing of settings while I learn how to print well.

Sunday, June 12, 2011

Parts are here!

My kit arrived yesterday with everything except the heated bed. I can't wait to dive in but I have other priorities until later this week. For now I have just opened the box and pulled out some of the RP parts to inspect.

The quality is very good. One of my friends has offered to help solder up the RAMPS electronics in return for being able to use the machine for some of his project ideas. Overall this should get everything up and running a little quicker. I'll post later this week once I get my workbench cleared and start digging into everything.

The quality is very good. One of my friends has offered to help solder up the RAMPS electronics in return for being able to use the machine for some of his project ideas. Overall this should get everything up and running a little quicker. I'll post later this week once I get my workbench cleared and start digging into everything.

Wednesday, June 1, 2011

Making keys with a Reprap

This guy has figured out how to make a parametric key printer, just type in the pin code and out pops a plastic key. It reminds me of the "credit card keys" AAA used to give out for getting into your car. Probably not good for long term use but great in a pinch.

eclecticc

eclecticc

Subscribe to:

Posts (Atom)